FL沸腾流化床造粒机可应用于制药、食品和化工行业。它特别适用于片剂、速溶饮料颗粒和调味品的制粒。

FL沸腾制粒干燥机

Transform materials into uniform granules effortlessly with our high-performance granulating machine.

混合、制粒、干燥和包衣一步完成。

高效双室滤袋除尘系统。

颗粒成型均匀,粉末含量低。

可选的防爆设计增强了安全性。

广泛应用于制药、食品和化学工业。

简化生产流程以提高效率。

清洁无尘的操作环境。

符合GMP准则的高质量颗粒生产。

描述

FL沸腾制粒干燥机

FL沸腾流化床造粒机可应用于制药、食品和化工行业。它特别适用于片剂、速溶饮料颗粒和调味品的制粒。

特点

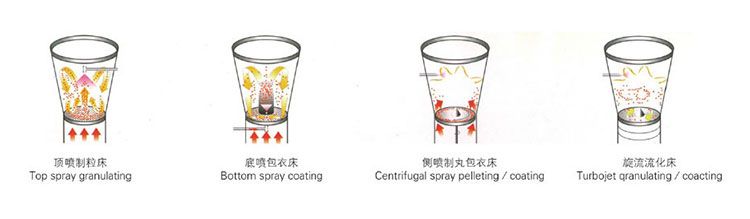

一步操作:将混合、制粒和干燥功能合并到一个操作中,简化了生产并提高了效率。

双室滤袋系统:有效除尘,确保洁净无尘的操作环境。

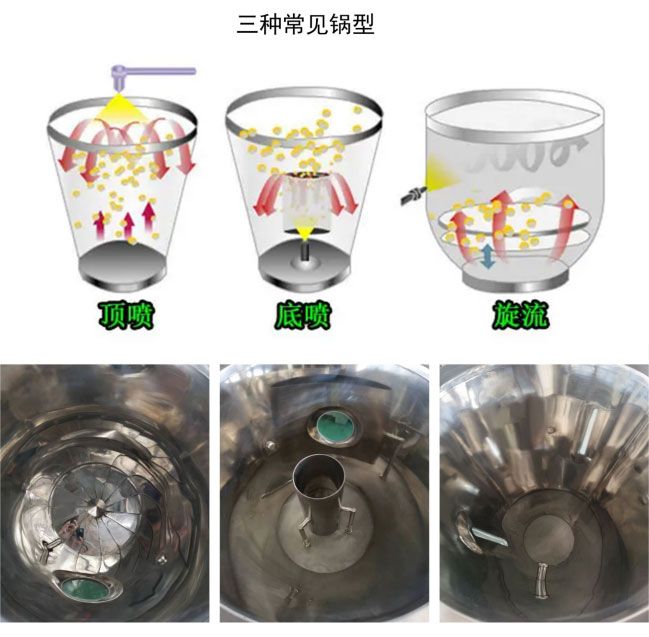

多流体喷嘴:确保颗粒形成均匀,粉末含量低,从而产生高质量的颗粒。

可选防爆设计:提供2巴防爆设计选项,以提高处理爆炸材料的安全性。

FL流化床造粒机是一种先进的设备,设计用于粉末材料的混合、造粒、干燥和包衣操作。它的特点是一步操作,结合了多种功能并提高了生产效率。双室滤袋系统可有效除尘,保持清洁的工作环境。多流体喷嘴保证颗粒均匀成型,粉末含量最少,从而获得高质量的颗粒。对于处理爆炸性材料的环境,该设备提供可选的防爆设计以提高安全性。FL流化床造粒机遵循GMP指南制造,是各种行业的可靠解决方案,包括制药、食品和化工行业。

FL沸腾制粒干燥机视频

成品展示

参数

| 参数 Item | 型号 Specification | ||||||||||||||

| Name | Unit | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | 800-1000 | |

| 容器容积 Container Volume | L | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 550 | 670 | 1000 | 1500 | By client | |

| 生产能力 Capacity | kg/batch | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | ||

| Steam | 蒸汽压力 Pressure | Mpa | 0.4-0.6 | ||||||||||||

| 蒸汽耗量 Consumption | kg/h | 15 | 18 | 35 | 60 | 99 | 120 | 130 | 140 | 161 | 180 | 310 | 400 | ||

| Power of fan | kw | 2.2 | 3 | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | 30 | 45 | ||

| 功率Power of electricity heater | kw | 6 | 9 | ||||||||||||

| 噪音Noise | db | Not more than 75dB Separated of fan | |||||||||||||

| Compressed air | Pressure | Mpa | 0.4-0.6 | ||||||||||||

| Consumption | m3 /min | 0.3 | 0.3 | 0.6 | 0.9 | 0.6 | 0.9 | 0.9 | 0.9 | 0.9 | 1.1 | 1.1 | 1.5 | ||

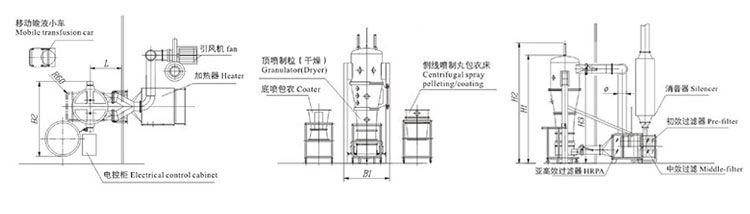

参考安装尺寸 Installation size forreference | H1(mm) | 2600 | 2600 | 2100 | 2250 | 2250 | 2850 | 2850 | 2850 | 2850 | 3300 | 3500 | 3850 | ||

| H2(mm) | 250 | 320 | 420 | 490 | 540 | 590 | 640 | 690 | 790 | 890 | |||||

| H3(mm) | 1900 | 2050 | 2050 | 2600 | 2600 | 2600 | 2600 | 3180 | 3380 | 3680 | |||||

| B 1 (mm) | 1550 | 1650 | 1010 | 1160 | 1260 | 1460 | 1560 | 1660 | 1760 | 1860 | 2060 | 2260 | |||

| B 2 (mm) | 1500 | 1800 | 2060 | 2460 | 2660 | 2860 | 3060 | 3260 | 3660 | 4060 | |||||

| ф 1(mm) | 300 | 400 | 550 | 700 | 860 | 1000 | 1100 | 1200 | 1300 | 1400 | 1600 | 1800 | |||

| ф 2(mm) | 150 | 180 | 180 | 180 | 250 | 280 | 280 | 280 | 280 | 280 | 315 | 355 | |||

| L (mm) | 850 | 1000 | 1100 | 1250 | 1530 | 1530 | 1530 | 1650 | 1650 | 1650 | 1750 | 1850 | |||

详情

样册下载Brochures Download

相关产品

让我们一起找到您想要的产品

期待您的垂询