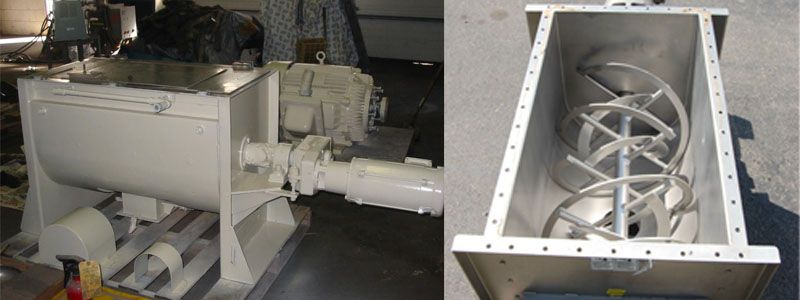

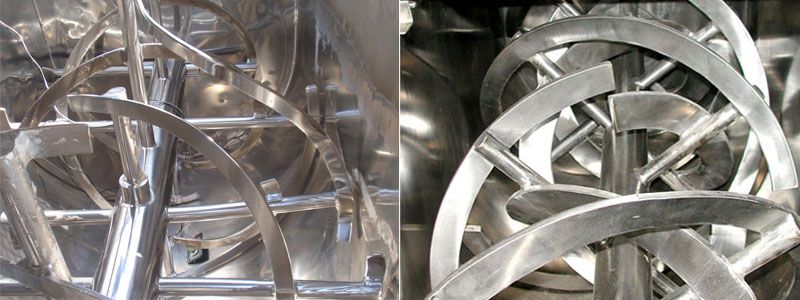

WLDH系列水平带式混合机是专为混合粘性或粘性粉末物料而设计的。它也适用于混合需要添加液体或糊状材料的粉末。这种混合器在需要大量输出并且不需要频繁更换材料种类的情况下特别有用。但是,应该注意的是,当处理粘性材料时,清洁可能具有挑战性。

WLDH系列螺带混合机

Discover the perfect blend of efficiency and versatility with our powder mixer, ensuring homogeneous mixing of powders for a wide range of industries and applications.

下载

下载