GTJ系列全陶瓷流化床气流粉碎机广泛应用于高科技陶瓷、锂电池、精细化工、电子、食品和制药等行业。它特别适用于需要精确粒度分布且对粗颗粒敏感的材料。它也是高硬度磨料的理想选择。

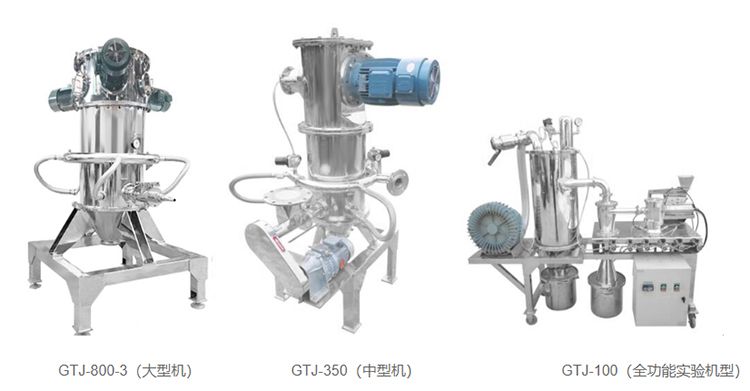

GTJ全陶瓷流化床气流粉碎机

Efficient and precise pulverization for enhanced material processing and production with our advanced pulverizer machine.

高效的“碰撞式”破碎原理。

低磨损和维护成本。

精确产品排放的集成设计。

耐磨陶瓷保护。

可定制特殊耐磨钢选项。

适用于闭路粉碎和惰性气体保护。

非常适合高科技陶瓷、锂电池、精细化学品等。

自动化生产线集成,绿色环保。

描述

GTJ全陶瓷流化床气流粉碎机

GTJ系列全陶瓷流化床气流粉碎机广泛应用于高科技陶瓷、锂电池、精细化工、电子、食品和制药等行业。它特别适用于需要精确粒度分布且对粗颗粒敏感的材料。它也是高硬度磨料的理想选择。

特点

1.“碰撞式”破碎原理,实现高效能源利用。

2.由于空腔影响最小,磨损和维护成本低。

3.破碎和分级一体化设计,产品出料均匀可控。

4.耐磨陶瓷保护,防止金属杂质污染。

5.带有特殊耐磨钢选项的可定制型号。

6.适用于闭路粉碎和惰性气体保护。

7.非常适合高科技陶瓷材料、锂电池电极材料、精细化学品等。

8.自动化生产线集成,绿色环保。

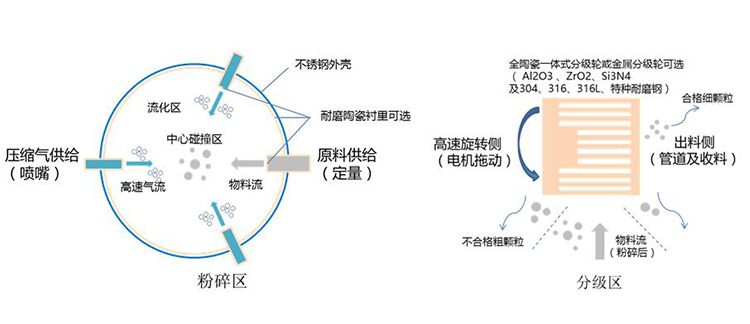

GTJ系列全陶瓷流化床气流粉碎机基于“碰撞式”粉碎原理工作,利用高能量利用率的压缩气体。粉碎喷嘴产生的高速气流均匀分布工作介质,加速了细化颗粒。然后,这些颗粒在分级室中由高速分级转子进行筛选,确保没有大颗粒的窄分布范围。

关键部件,包括进料机构、腔衬、喷嘴、分级转子、密封机构和卸料系统,均采用耐磨陶瓷保护。这种设计符合高科技材料的要求,并防止金属杂质污染。专利产品全陶瓷高速分级转子可精确控制分级粒度。

GTJ系列全陶瓷流化床气流粉碎机可以根据特定的行业需求进行定制,提供304、316、316L或其他特殊耐磨钢的型号。它还可以根据材料特性促进闭路粉碎和惰性气体保护。凭借其耐用性和实现精细粒度分布的能力,它被广泛应用于各种应用领域,包括高科技陶瓷、锂电池、精细化学品、电子产品等。

该设备无缝集成到自动化生产线中,确保无灰尘泄漏,并提供绿色环保的解决方案。它降低了劳动强度,并提供智能在线和远程控制功能。

Finished Product Display

参数

| Specifications | GTJ-100 (Micro type/Lab-scale) | GTJ-200 | GTJ-250 | GTJ-350 | GTJ-500 | GTJ-630 | GTJ-800-2 | GTJ-800-3 |

| Gas consumption(m³/min) | 1.5 | 3 | 6 | 10 | 20 | 30 | 40 | 60 |

| Crushing pressure(Mpa) | 0.4~1.2 | 0.4~1.2 | 0.4~1.2 | 0.4~1.2 | 0.4~1.2 | 0.4~1.2 | 0.4~1.2 | 0.4~1.2 |

| Feed size(mesh) | 60~325 | 60~325 | 60~325 | 60~325 | 60~325 | 60~325 | 60~325 | 60~325 |

| Output particle size(D50,μm) | 0.5~30 | 0.5~30 | 0.5~30 | 0.5~30 | 0.5~30 | 0.5~30 | 0.5~30 | 0.5~30 |

| Capacity(kg/h) | 0.3~10 | 1~30 | 3~80 | 5~200 | 10~400 | 20~600 | 30~1000 | 80~3000 |

| Air compressor power(kW) | 11~15 | 22~30 | 45~55 | 75~90 | 132~160 | 200~250 | 250~300 | 400~450 |

| Main power(kW) | 1.1 | 2.2 | 3 | 4 | 5.5 | 11 | 11 | 16.5 |

FAQ - Have any questions?

What is the GTJ Series · All Ceramics Fluid-bed Jet Mill?

The GTJ Series · All Ceramics Fluid-bed Jet Mill is a specialized machine used for grinding and pulverizing materials using high-speed jets of compressed air or gas.

What are the key features of the GTJ Series · All Ceramics Fluid-bed Jet Mill?

The key features of the GTJ Series · All Ceramics Fluid-bed Jet Mill include all-ceramic construction, high grinding efficiency, precise particle size control, low contamination, easy operation, and versatile application capabilities.

How does the GTJ Series · All Ceramics Fluid-bed Jet Mill achieve high grinding efficiency?

The GTJ Series · All Ceramics Fluid-bed Jet Mill utilizes high-speed jets of compressed air or gas to create a turbulent zone within the grinding chamber. This turbulence enhances particle-to-particle collisions, resulting in efficient grinding and pulverization.

Can the GTJ Series · All Ceramics Fluid-bed Jet Mill control the particle size of the ground materials?

Yes, the GTJ Series · All Ceramics Fluid-bed Jet Mill offers precise particle size control. It allows users to adjust the operating parameters, such as feed rate, gas pressure, and classifier speed, to achieve the desired particle size distribution for their specific application requirements.

What are the advantages of the all-ceramic construction of the GTJ Series · All Ceramics Fluid-bed Jet Mill?

The all-ceramic construction of the GTJ Series · All Ceramics Fluid-bed Jet Mill ensures low contamination and high purity of the ground materials. It is particularly suitable for grinding and pulverizing sensitive materials, such as pharmaceuticals, chemicals, and advanced ceramics.

Is the GTJ Series · All Ceramics Fluid-bed Jet Mill easy to operate?

Yes, the GTJ Series · All Ceramics Fluid-bed Jet Mill is designed for easy operation. It features user-friendly controls, intuitive interfaces, and automated or semi-automated operation modes, depending on the specific model.

What materials can be processed using the GTJ Series · All Ceramics Fluid-bed Jet Mill?

The GTJ Series · All Ceramics Fluid-bed Jet Mill can process a wide range of materials, including powders, granules, and agglomerates, such as pharmaceutical ingredients, chemicals, ceramics, and other similar substances.

Does the GTJ Series · All Ceramics Fluid-bed Jet Mill require additional equipment for material feeding and collection?

Yes, the GTJ Series · All Ceramics Fluid-bed Jet Mill typically requires additional equipment, such as a feeding system and a cyclone or bag filter for material collection. These accessories ensure efficient material handling and dust control during the grinding process.

Can the GTJ Series · All Ceramics Fluid-bed Jet Mill be used for heat-sensitive materials?

Yes, the GTJ Series · All Ceramics Fluid-bed Jet Mill is suitable for grinding heat-sensitive materials. The low-temperature grinding environment created by the compressed air or gas jets helps to minimize heat generation and maintain the integrity of heat-sensitive substances.

Where can I find technical support or spare parts for the GTJ Series · All Ceramics Fluid-bed Jet Mill?

Technical support and spare parts for the GTJ Series · All Ceramics Fluid-bed Jet Mill can be obtained by contacting NOAH(yznoah@noah-pm.com). They will provide the necessary assistance, troubleshooting, and supply of genuine spare parts to ensure optimal performance and longevity of the equipment.

详情

样册下载

相关产品

让我们一起找到您想要的产品

期待您的垂询