该机符合GMP标准

防油和防尘系统

整体采用严密的密封和防尘设计

采用高清晰、可见视窗设计

便于拆卸的结构,可维护性好

压片室360°结构,便于观察、清洁。

产品详情:

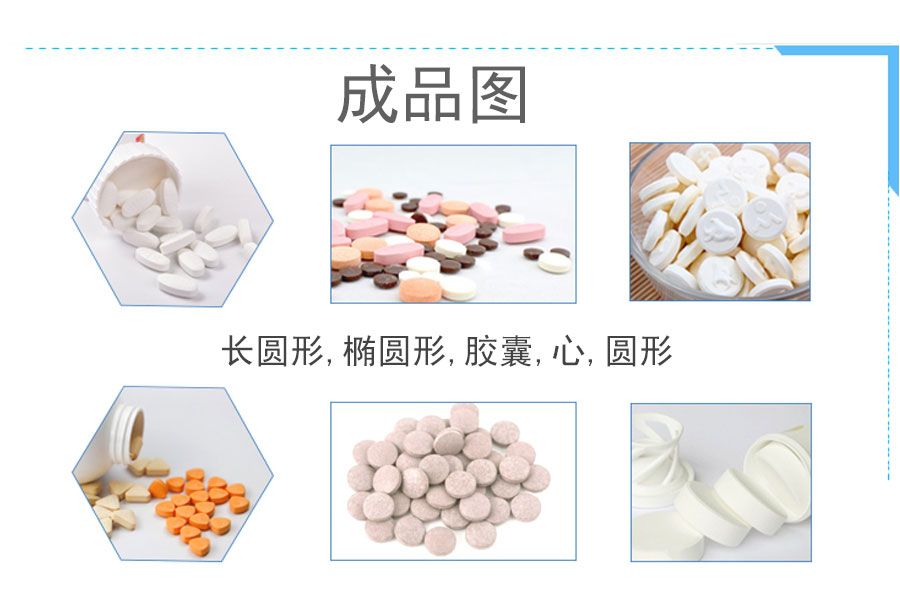

本机用于将颗粒状原料压制成药品,化工,食品,电子等行业的片剂,适用于大量生产和压制多种圆形或异形片剂,糖片,钙片等,不适用于压制半固定,湿粉末和较细颗粒粉末(≥100目)

GZP250系列智能旋转式压片机

特点

该机符合GMP标准

防油和防尘系统

整体采用严密的密封和防尘设计

采用高清晰、可见视窗设计

便于拆卸的结构,可维护性好

压片室360°结构,便于观察、清洁。

特点Features

新型支撑结构,承载能力强,适合压制中药片、异型片;

加料系统封闭,漏粉率低(与调试有关);

采用变频电机,产量连续可调。

上下冲头过紧保护、超载保护、紧急停车、故障报警

两次成型液压,主压力和预压力、充填深度及压片产量可以连续调节;

采用触摸屏电脑控制系统,具有主电机断路故障显示、停机功能、及其它故障显示和报警功能。

有强制送粉,除尘功能。

主驱动系统

主驱动系统的功能是为压片机提供压片动力。这里要求主驱动系统速度可调。而且在高冲击负荷下具有足够的扭矩、速度稳定性和可靠性。

本机采用变频技术,节能降耗的优点,控制可靠,运行稳定,噪音低,变频器具有过压、低压、过流等多种保护功能。可以通过输出对执行机构进行实时监控,如果异常,保护功能被激活,变频器将停止输出,并显示错误信息,指出故障原因,进一步保证电机工作的安全性和可靠性。

强制进料装置

强制进料装置由连接到轴上的主轴驱动,该轴穿过两个同步皮带轮、万向节、联轴器、强制进料器、储罐、管道、进料平台和调平腿机构。

GZP250系列智能旋转式压片机视频

成品展示Finished Product Display

参数规格Specification

| 型号Name | GZP-26 | GZP-22 | GZP-17 |

| 冲模数Number of station | 26 | 22 | 17 |

| 冲模Punch standard(EU standard) | EU BB | EU B | EU D |

| 压片产量(片/小时)Max. Output(pcs/h) | 120100 | 101600 | 78500 |

| 最大主压力Max. Main Compression Force(KN) | 100 | 100 | 100 |

| 最大预压力Max. Pre-compression Force(KN) | 16 | 16 | 16 |

| 最大压片直径(Max. Tablet Diameter(mm) | 10 | 16 | 22 |

| 最大充填高度(Max. Filling Depth(mm) | 12 | 12 | 16 |

| 最大压片厚度Max. Tablet Thickness(mm) | 6 | 6 | 8 |

| 主电机功率Main motor power | 5.5KW | ||

| 电机转速Rotary speed | 1430r/m | 1430r/m | 970r/min |

| 电源要求Voltage Frequency | 380V 50HZ OR customized | ||

| 空载噪声值Noise Db(A) | <75 | ||

| 机器外形尺寸Overall size (m) L x W x H | 1X1.2X1.7 | ||

| 机器净重Main weight (Kg) | 1250 | ||

详情

宣传册下载Brochures Download

相关产品

让我们一起找到您想要的产品

期待您的垂询